There's no annual MOT (roadworthiness test) in France. Which is nice as it saves one's pocket money. However, it is up to the individual rider to make sure their machine is roadworthy, for their own peace of mind.

I was browsing through the service-and-repair manual, when I came across a section on brake hoses. It stated that these should be replaced after a certain amount of time. Unfortunately the specific time interval was not mentioned; this falling under the "unscheduled maintenance" section. Well, to the best of my knowledge, the ST1100 still had its original brake and clutch lines. And as it was now fourteen years old, it was probably time to change these.

Having done some research, I found that as a brake hose ages, it becomes more "spongy" and can bulge under pressure. So not all of the pressure you're exerting on the brake lever / brake pedal is being transmitted to the brake pads. I decided to replace the OEM hoses with HEL stainless steel braided ones - and for good measure, the clutch hose as well.

The procedure is fairly simple; drain the existing fluid, remove the old hose, install the new hose (with new banjo bolts and washers), refill with fresh brake fluid, and bleed the system. Changing the front brake hose and the clutch hose was fairly straightforward.

The rear brake lines however, required the removal of the fuel tank. Here's the new rear brake line installed:

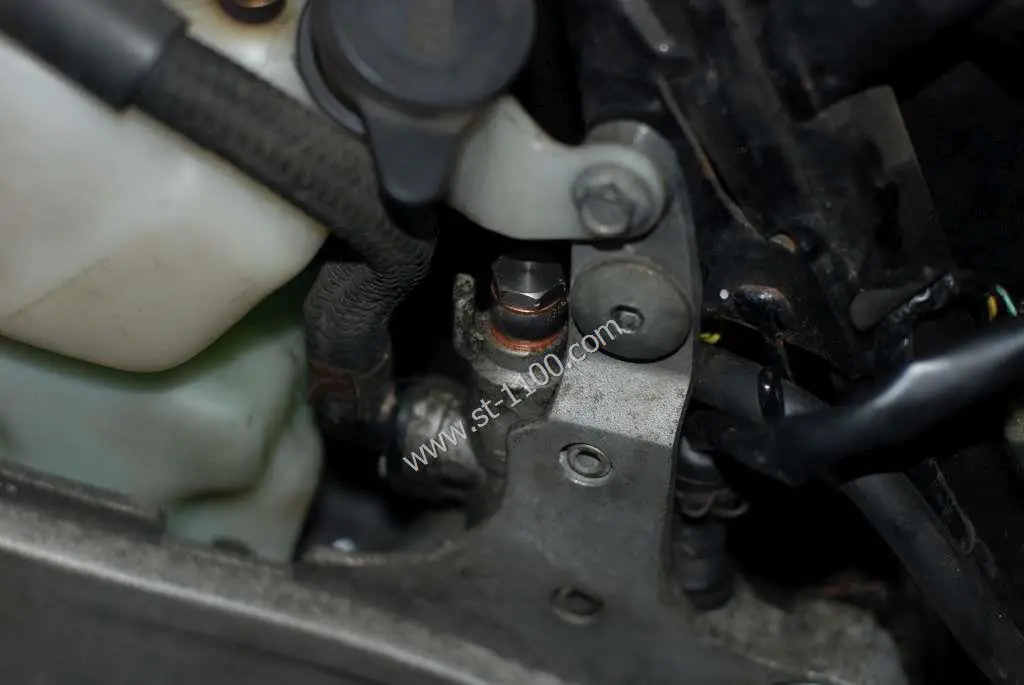

It was difficult to photograph the other end of the rear brake line, but you can at least see the new banjo bolt and washers in the next photo. I wonder why it's called a banjo bolt?

Once everything was reinstalled, refilled, and bled, I went for a test ride. The brakes actually seem much sharper, and there appears to be less pedal/lever travel; although this could just be my impression. The clutch also still works, which is A Good Thing.

At least now I won't have to worry about the brake hoses again for at least another fourteen years...